The Tire Cologne

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/Kachel_TireCologne.jpg)

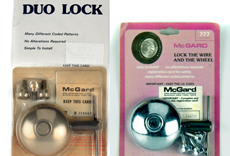

For over 50 years, McGard, a global player with about 700 employees, has been committed to the development of locking systems. McGard dominates the market for wheel rim locks and supplies nearly every vehicle manufacturer worldwide. In 1994, McGard Deutschland GmbH was founded to cater to the European market and our customers here.

The hallmark of our employees is their palpable identification with and sense of responsibility for our products. This is also reflected in our corporate policy.

It firmly anchors the most important pillars such as employee and customer satisfaction, but also environmentally conscious action.

30 years of McGard in Germany.

McGard expands its manufacturing and office space.

Expansion QA Laboratory.

McGard Deutschland GmbH celebrates 25th anniversary.

McGARD world leading manufacturer of wheel lock systems.

McGard Singapore inaugurated.

Expansion of the office space in Nordheim.

Annex – Extension to the production hall in Nordheim.

McGard Deutschland GmbH Customer Service online shop went online in April 2011.

In view of the encouraging trend and with an eye to future expansions, McGard Deutschland GmbH moved into its new building in Nordheim in August 2005.

In 1999, McGard Japan was inaugurated in Oomiya City

McGard GmbH was set up in 1994 in Flein (Baden-Württemberg), Germany.

In 1990 McGard relocated to the new plant covering 17,187 m2 in Orchard Park, New York.

In 1980 the McGard Special Products Division was set up to develop mechanical safety products for all applications outside the automotive sector.

Over the years McGard has commenced supplying almost every OEM import and home vehicle manufacturer worldwide, but has still retained an additional strong position on the retrofit market.

In 1977 McGard LLC entered the OEM sector by launching a stainless steel lock for Cadillac hub caps.

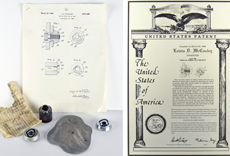

In 1966 Lewis McCauley patented the first one-part wheel lock design. In the late sixties and early seventies, the demand for wheel locks continued to grow.

The year 1964 witnessed the first rough development of a one-part wheel lock. A local car dealer needed a product to stop theft of his cars’ wheels. He had since been robbed of the wheels for the new vehicle line.

In 1959 Lewis D. McCauley took over a small machine shop with three employees and installations.

Our high level of consulting expertise and versatility supports the strong position of McGard on the market. Our profile finds its perfect complement in our overall concept extending over development, production, and delivery and in the aftersales support provided by our customer service. Your needs are our challenge.

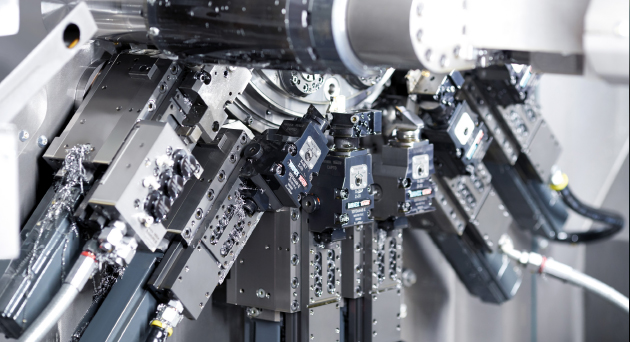

Backed by the knowhow of our personnel in conjunction with state of the art production processes and plant technologies, we safeguard the highest level of manufacturing quality for our products.

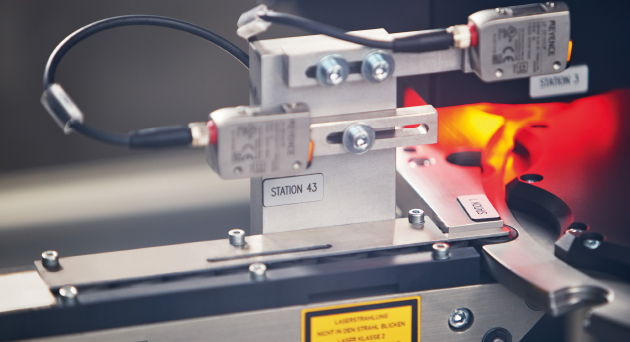

Step 1

Custom steel

Step 2

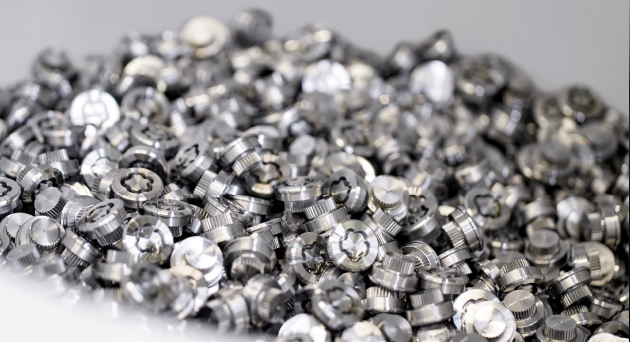

Manufacture of wheel locks

Step 3

Hardening and plating

Step 4

Press fitting

Step 5

Testing and sorting

Step 6

Storing

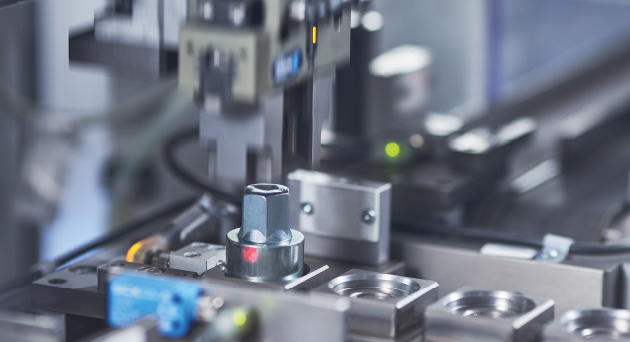

Step 1

Machining of keys

Step 2

Hardening and plating

Step 3

Testing and sorting

Step 4

Press fitting

Step 5

Labelling and packaging

![[Translate to Englisch:] McGard-storing-key [Translate to Englisch:] McGard-storing-key](/fileadmin/Seiten/Unternehmen/Prozessketten/en/McGard_Prozesskette_Schluessel_6.jpg)

Step 6

Storing

McGard wheel locks provide the greatest possible protection against theft of rims and tyres.

Our customers include the main vehicle manufacturers as well as industrial companies from Europe, Japan, and North America.

The management system and all activities of McGard Deutschland GmbH comply with the requirements of the internationally applicable

environmental management (DIN EN ISO 14001:2015), quality management (IATF 16949:2016)

health and safety management (DIN EN ISO 45001: 2018) and information security (TISAX).

Our products reflect our company philosophy towards quality assurance and environmental management.

Our customers include the most important vehicle manufacturers in Europe, Japan, and North America. McGard has received many accolades, including the Total Quality Excellence Award from the Ford Motor Company. An award that has been granted to only a few companies throughout the world. This honor underscores our commitment to 100% quality, so we are particularly proud of it.

Our company prioritizes the protection of the environment, consumers, and employees. On an equal footing with our top priority objective to expand our market position is our responsibility towards our employees and our impact on the environment. For this, we integrate environmentally relevant aspects in our processes and products. The management board is committed explicitly to the consistent observance of all laws, regulations, and standards relevant to the environment.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/Kachel_TireCologne.jpg)